| Circuit

breakers and SF6 |

|

|

|

Circuit breakers are used in High voltage

DC and AC applications for swithcing of powerlines,

transformers, reactors and capacitors. One phase and

three phase operations up to 800kV, 63kA. |

|

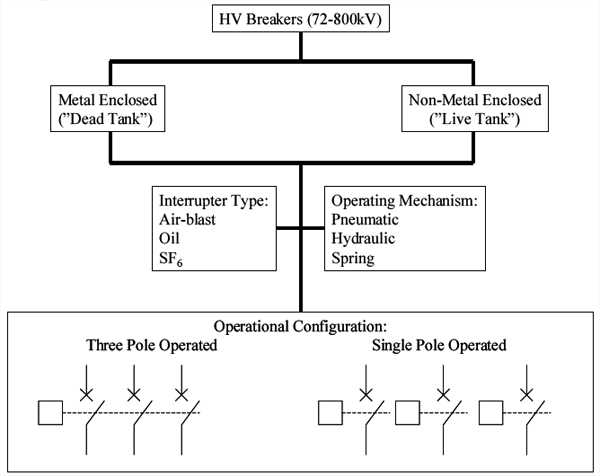

There is a wide

variety of HV circuit breaker designs and configurations

in existence. They can be classified in various ways,

but the most common classifications are described in the

figure below. |

A circuit breaker has several main functions:

• Conduct rated currents when closed

• Maintain rated insulation withstand across its contacts when open

• Close its circuit always and only on command

• Open or interrupt its circuit always and only on command, according to

its ratings |

| |

|

|

|

| From

air-blast and oil to SF6 and springs |

|

|

|

From a historical

perspective oil and air-blast interrupters are the

oldest designs and essentially have been superceded by

SF6 interrupters since the mid-1980’s. There has also

been an increasing trend towards the use of spring

operating mechanisms from the early 1990’s, following

from the results of the second CIGRÉ enquiry into the

reliability of HV breakers. |

|

Service and testing of

circuit breakers evolve arround the electrical and

mechanical functions in order to ensure a secure and

steady elcetrical power flow. Non working breakers is an

expensive event for utilities, power companies and

manufacturers. As you can see in the conclusions below

the criterias for analysing the SF6 gas is obvious. |

| |

|

|

|

CIGRÉ report 13-202

draws some important general conclusions regarding the

most common problems with breakers, including:

• Operating mechanisms are the sub-assembly with the

most failures – further work was suggested to “simplify

the electrical and mechanical control process”.

• While only 7% of major failures in SF6 breakers were

attributed to loss of gas, approximately 40% of minor

failures were due to this problem, leading to the

conclusion that additional effort was needed (in the

early 1990’s) to address SF6 gas pole sealing and

monitoring.

• Additional type testing for mechanical endurance,

climate testing and life cycle assessment were

recommended (see later discussion on impacts on

revisions to IEC breaker standards).

• Encouragement was made for the use of “common

definitions for reliability studies and maintenance

techniques”.

|

|

Environment |

|

|

|

The need for testing of the sf6 gas is

not only to protect the electric power equipment but

maybe more importantly in order to protect our

environment A high productive

circuit breaker factory for live tank air insulated

breakers consumes approximately 50 tons of SF6 gas each

year. A deadtank circuit breaker factory consumes 10

times that amount.

A single live tank air insulated circuit breaker

contains somewhere from e few kilos up to a few tens of

kilos. While a Deadtank breaker as stated previously

consists of tens times as much. |

|

And as you may all be aware, a GIS substation can

contain several tons of Sulphur Hexaflouride.

Even though the sf6 insulated switchgear development has

managed to produce compact designs that reduces space

reduction up to 98% compared to air insulated switchgear

and has reduced the SF6 volume up to 75% with leakage

rates down to 0,5% per comparttment and year.

Air

insulated breakers is still considered to be the best

choice for our environment. |

| |

| |

|

Air insulated breaker (HPL) |